Dust control and wetblasting – Containment and control for specialized projects

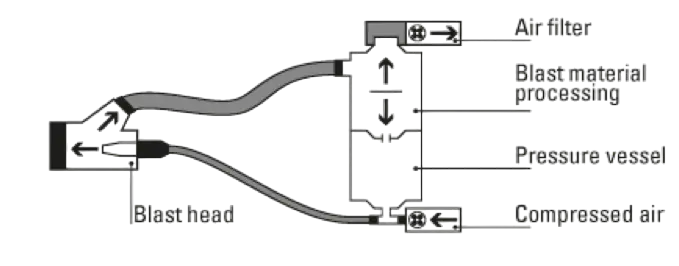

Clemco dust control systems with closed-circuit can be used to blast virtually anywhere. No elaborate containment or housing is needed. A closed-circuit blast system emits no abrasive particulate or dust and consumes a minimum amount of energy while maintaining the blast stream in a contained, safe pattern.

Dust-controlled blasting – Environmental protection

«Clemco offers multiple solutions for open blasting with a minimum of dust production and environmental impact»

The closed-circuit and dust control systems from Clemco enables flexible blasting in many different outdoor and indoor locations, with minimal dust escape. Dust control equipment offers a closed-loop system that delivers abrasive to the surface while simultaneously recovering and reclaiming it and preventing dust egress. Different blast heads can be used to conform to different shapes and surface patterns, all while keeping the surrounding environment free of dust pollution.

- • Environmentally protective closed loop system

- • Cost savings through media reclamation

- • No dust problems

- • Simple operation

- • Robust, reliable, durable systems

Closed-circuit system components

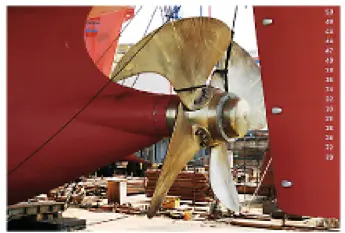

Wide range of applications

Repair work in clean environments

For sensitive surfaces

Light to medium corrosion

Wetblasting systems – High-performance options for cleaner blasting

«Wet-blast control systems keep abrasive dust to the absolute minimum»

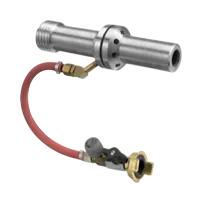

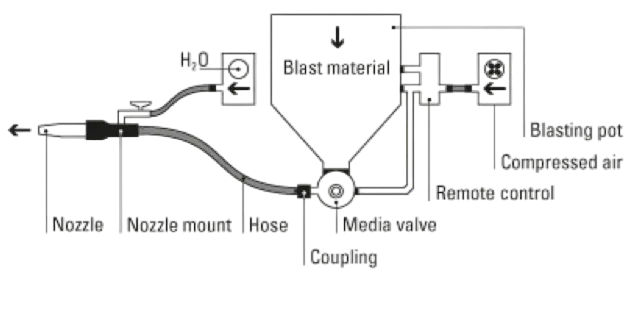

Clemco‘s wetblast injector system acts as a dust control screen, trapping excess dust in a curtain of water without sacrificing any blast stream impact.

The injected water maintains a 360° controlled curtain of water to trap dust, while enabling the blast stream to clean surfaces quickly and effectively.

The wetblast injection system has widespread applicability, and can be used in any environment in which excess abrasive dust is a concern. The injection of water into the blast stream improves blast visibility, helps coating adhesion, and removes the need for blast containment.

Clemco wetblast systems allow for usage in the following configurations:

1. Damp-blasting with blast material, compressed air and water

2. Washing with accelerated water using compressed air

3. Blow-cleaning and drying with pure compressed air

System components

Wide range of applications

Repair work in clean environments

Light to medium heavy contamination